Our design standards are as

meticulous as our components

ADVANCED Mold Manufacturing FOR medical devices

Micro Mold and Plastikos strategically go-to-market as a unified operation. Our ability to provide our clients with full-service design, build, and production molding capabilities improves communication and efficiency throughout the entire product’s life cycle. Our client’s molds are designed with the finished product in mind, whereby we design each custom mold around the part geometry to ensure maximum cooling, venting, sub-inserting, and overall maintenance items. We remain solely focused on manufacturing complex, tight tolerance applications molded from engineering grade materials with cavitation ranging from single-cavity to 96-cavity.

Our captive tooling capabilities within Micro Mold exceed 15,000 square feet of manufacturing space and fully equipped with 3-axis and 5-axis high-speed milling centers along with CNC EDM centers that are integrated with 3-axis robotics to handle lights-out manufacturing. With more than 450 years of collective experience within our tooling group, Micro Mold continues to exceed over 97% on-time delivery for new tools once the project begins.

IN-HOUSE MOLD DESIGN

Micro Mold's team of mold designers have extensive backgrounds in plastic & mechanical engineering. Our molds are meticulously designed to address maximum cooling & alignment, mold longevity, cavity-to-cavity tolerancing, and ease of maintenance, to name a few.

INTEGRATED ROBOTICS

Many of our CNC Milling and CNC EDM centers have been integrated with 3R robotic systems. This provides advanced lights-out manufacturing capabilities throughout out facility, thereby reducing mold lead times and maximizing our manufacturing efficiency across all departments.

ADVANCED CNC MILLING & CNC EDM

We have invested in the latest high-speed 3-axis and 5-axis CNC Milling technology through Yasda and DMG-Mori as we continue to advance hard milling applications. Additionally, all our wire and sinker EDM centers have been standardized through Mitsubishi to maintain the accuracy and finish that our customers require in the final device.

INTERNAL MOLD SAMPLING + R&D

Micro Mold's in-house mold sampling and R&D center is equipped with the latest molding technology, which allows our engineers to conduct initial mold trials, and R&D efforts off-line from the production environment at Plastikos. Once a mold is ready for qualification, data is transferred to our molding operation to reduce overall qualification time.

INNOVATIVE MOLD DESIGN TO ENSURE

MOLD LONGEVITY

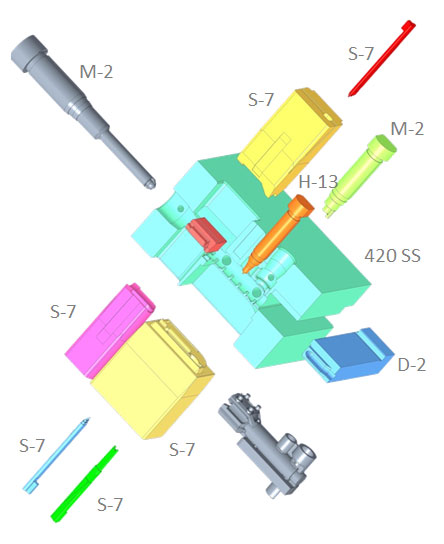

Optimizing a mold design for injection molding is vital to the overall success of any device, whether its medical, electronics, automotive, and so on. Selecting key elements such as the gate location, runner system design, ejection method, and cooling technique are essential to the longevity of the mold and overall part quality. Ultimately, our goal is to design and fabricate a mold that is well-suited for the part geometry, chosen plastic material, and expected annual volume.

Shown below are just some of the key considerations our team of engineers must account for during the preliminary and final design reviews before each injection mold is ready for fabrication:

GATING & RUNNER SIZING

When gating a part, we need to consider wall thickness variations. Most often, gating in the thickest region of the part is optimal to prevent sinks and other molding related defects. Also, venting last place to fill and other regions of the mold that could trap gas and lead to both performance and cosmetic defects. Runner systems must be geometrically, and shear balanced to ensure even filling. Sizing both the gate and runner is largely dependent on the raw material characteristics. A flow simulation is often a helpful tool to address sizing both runner and gates.

COOLING LAYOUT FOR MAXIMUM CYCLE TIME EFFICIENCY

Uniform cooling is essential to minimize part defects that are directly related to cooling as well as reducing the cycle time. Again, a flow simulation is an excellent tool to utilize in conjunction with runner and gate sizing to optimize the cooling layout of a mold. Cooling lines should be designed to achieve an adequate flow rate. Calculating a Reynolds number greater than 10,000 is a useful method to determine adequate flow rate through the water line(s)

Steel selection & sub inserting is extremely important during the mold design phase of the project. Often, the steel selection is based on the plastic material, volume, and part geometry.

ADVANCED MACHINING CONSIDERATIONS FOR PRECISION MOLD FABRICATION

The specific machining operation largely depends on the part geometry and surface finish. When possible, our team at Micro Mold will utilize hard milling capabilities through our 5-axis machining centers, as it's proven to reduce overall machining time and provide micron-level accuracy. However, often the part geometry will require the use of secondary operations through CNC EDM. The specific machining operation (hard milling, EDM, turning, etc.) are largely driven off the part’s geometry and carefully considered throughout the project. Each department offers lights-out manufacturing with integrated robotics for maximum efficiency in mold fabrication.

Steel selection and machining tolerances play a crucial role in project success, especially when building SPI 101 style-tools for over a million cycles. Additionally, sub-inserting components help minimize downstream costs and time for replacement inserts. Our precision molds are designed with multiple levels of alignment to reduce cavity and core wear. Machining tolerances are often held to less than +/- 0.0001” in steel in certain applications, especially on product geometry that contains +/- 0.001” on the finished device.

STEEL SELECTION FOR

PRECISION MOLD FABRICATION

Steel selection and the level of sub inserting are determined by numerous considerations, such as: project complexity, annual volume, surface finish, and

abrasiveness of the resin. Certain polymer materials can be rather abrasive, and some, corrosive to steel. For this reason, it’s crucial to understand the

behavior of the various resins on the market, and the impact they will have when designing and building precision molds.

| Manufacturer | Quantity | 3R Robot Equipped |

|---|---|---|

| Mitsubishi EA8PS | 1 | |

| Mitsubishi EA12PS | 1 | |

| Charmilles Technology Roboform 20 | 1 |

| Manufacturer | Quantity | Workspace (W” x L”) |

|---|---|---|

| Mitsubishi FA 10S | 1 | 31″ x 23″ |

| Mitsubishi FA10 | 1 | 31″ x 23″ |

| Drillmate 403i-A | 1 | 17.50″ x 26.25″ |

| Manufacturer | Quantity | Chuck Diameter | 6 Axis Fanuc Robot Equipped |

|---|---|---|---|

| DMG MORI NLX 1500 | 1 | 6″ DIA |

| Manufacturer | Quantity | Workspace (W” x L”) | 3R Robot Equipped |

|---|---|---|---|

| Yasda 5-axis YMC650 | 1 | 19″ x 23″ | |

| DMG MORI 5-Axis NMV 3000 DCG | 1 | 13.8″ DIA | |

| DMG MORI 3-Axis NVD 1500 DCG | 2 | 9″ x 9″ | |

| MORI SEIKI 3-Axis MS NV 5000 | 1 | 20″ X 30″ | |

| MORI SEIKI 3-Axis MS SV 503 | 1 | 20″ X 40″ |

| Manufacturer | Quantity | Workspace (W” x L”) |

|---|---|---|

| Harig Surface Grinder | 2 | 6″ x 18″ |

| Okamoto | 8 | 6″ x 18″ |

| Okamoto X ACC16-32ST | 1 | 16″ x 32″ |

| Manufacturer | Model | Max. Press Tonnage | Quantity | Max. Barrel Size (oz.) | Tie Bar Height (in.) | Tie Bar Width(in.) | eDart Equipped |

|---|---|---|---|---|---|---|---|

| Arburg | 470 A | 88 | 2 | 3.9 | 18.5″ | 18.5″ |

PIONEERING THE FUTURE OF MEDICAL DEVICE MANUFACTURING WITH PRECISION, CARE, AND INNOVATION

If you’re ready to elevate your project with top-tier injection molding services, contact us today.