Mold design

& Fabrication

Optimizing a mold design for medical injection molding is vital to the overall success of any medical device. Selecting key elements such as the gate location, runner system design, ejection method, and cooling technique are essential to the longevity of the mold and overall part quality. Ultimately, our goal is to design and fabricate a mold that is well-suited for the part geometry, chosen plastic material, and expected volume.

General Considerations

- 1.) Has class of tooling been determined?

- 2.) Will the tool be dedicated to one part?

- 3.) Has the warranty on the tool been confirmed?

- 4.) Is the design provided by the mold builder?

- 5.) Are high wear areas sub-inserted for ease of replacement/repair?

- 6.) Have tool steels been determined and approved?

- 7.) Are spare components required?

- 8.) Will cavitation level meet annual estimated part usage?

- 9.) Will cavitation yield piece pricing that matches target range?

Runner & Gating

- 1.) Has gating location been determined and evaluated?

- 2.) Has gating style been determined?

- 3.) Will style allow the part to be automatically degated?

- 4.) Will gating style require secondary removal?

- 5.) Do annual volumes require hot manifold for piece pricing reduction?

- 6.) Is a hot manifold applicable for selected material?

- 7.) Is a cold runner sufficient for piece pricing target?

- 8.) Can gate be sub-inserted for ease of replacement or repair?

Mold Optimization - Gating

Location

| When gating a part, consider wall thickness variations. Most often, gating in the thickest region of the part is optimal to prevent sinks and other molding related defects. Consider venting last place to fill and other regions that could trap gas. |

Tolerancing

| When gating a part, consider wall thickness variations. Most often, gating in the thickest region of the part is optimal to prevent sinks and other molding related defects. Consider venting last place to fill and other regions that could trap gas. |

Weld Lines

| When gating a part, consider wall thickness variations. Most often, gating in the thickest region of the part is optimal to prevent sinks and other molding related defects. Consider venting last place to fill and other regions that could trap gas. |

Type

| When gating a part, consider wall thickness variations. Most often, gating in the thickest region of the part is optimal to prevent sinks and other molding related defects. Consider venting last place to fill and other regions that could trap gas. |

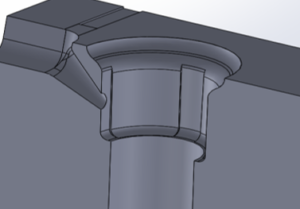

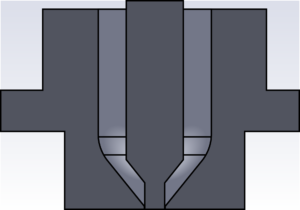

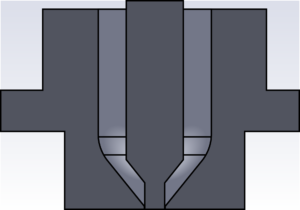

Tunnel Gate

Advantage Disadvantage |

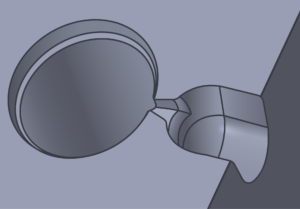

Tab Gate

Advantage Disadvantage |

Valve Gate

Advantage Disadvantage |

Mold Optimization - Gating

Geometry

| Runner systems should be geometrically balanced to ensure even filling . This means identical flow lengths to each cavity with adequate venting designed throughout. |

Tolerancing

| The steel accuracy from one runner branch to another is extremely important and often overlooked. Variations in steel can lead to unbalanced filling conditions within the mold. |

Size

| Runner sizing depends largely on the material type and length of flow. A flow simulation is often a helpful tool to accurately determine the proper runner size for a given material and mold cavitation. |

Type

| There are many types of runner system designs, each one with its own unique purpose. The table below illustrates a few common designs and their intended purpose. |

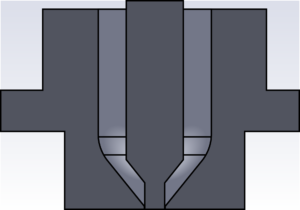

Full Round

Advantage Disadvantage |

Trapezoid

Advantage Disadvantage |

Hot Manifold

Advantage Disadvantage |

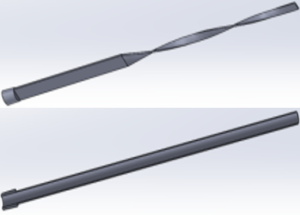

Mold Design & Fabrication: Design Optimization

Location

| When ejecting a part, it is important to select an area that will allow for adequate ejection while reducing the potential for part deformation or potential tooling damage. |

Tolerancing

| The fit between holes and pin/blade sizes should be within +/- 0.0003 inches to allow for a smooth fit but also reducing the risk for flash in this area. |

Size

| Over time, the ejection system within a mold will wear. It is recommended to utilize standard size components, whenever possible. |

Type

| There are many types of ejection designs, each one with its own unique purpose. The table below illustrates a few common designs and their intended purpose. |

Ejector Pins Blades Sleeves

Advantage Disadvantage |

Stripper Plate

Advantage Disadvantage |

Lifters

Advantage Disadvantage |

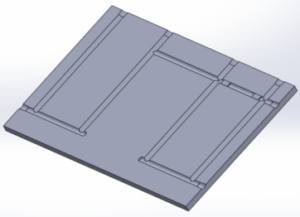

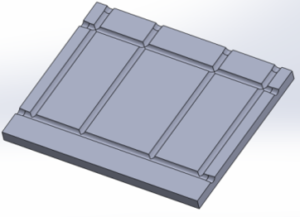

Mold Optimization – Cooling

Location

| Mold plates should be designed for maximum cooling or heating. Water line fittings should be placed on the non-operator side of the press and recessed into the mold plates, whenever possible. |

Uniform Cooling

| Uniform cooling is essential to minimize part defects that are directly related to cooling. A flow simulation is a helpful tool to accurately determine proper mold cooling. |

Size

| Cooling lines should be designed to achieve an adequate flow rate. Calculating a Reynolds number greater than 10,000 is a useful method to determine adequate flow rate through the water line(s). |

Type

| Cooling lines should be designed to achieve an adequate flow rate. Calculating a Reynolds number greater than 10,000 is a useful method to determine adequate flow rate through the water line(s). |

Series Circuits

Advantage Disadvantage |

Parallel Circuits

Advantage Disadvantage |

Baffles & Bubblers

Advantage Disadvantage |

Steel Selection & Maintenance

| Material | Hardness Rc | Mold Application | Wear Resistance | Polish (surface finish) | Ability to machine |

|---|---|---|---|---|---|

| P-20 | 28-34 | Cores Cavities Mold Bases Notes – Commonly used for pilot / prototype mold purposes | Poor | Good | Good |

| H-13 | 50-52 | Cores Cavities Holder blocks Notes – Very tough – Can be difficult to remove grinding burrs | Fair | Fair | Good |

| 420 Stainless | 52-54 | Cores Cavities Mold Bases Notes – Corrosion resistant | Fair | Good | Good |

| M-2 | 60-62 | Core Pins Notes – Good toughness | Good | Fair | Poor |

| S-7 | 55-57 | Cores Cavities Holder blocks | Good | Good | Good |

| D-2 | 60-62 | Gate inserts Notes: – Extremely wear resistant compared to other steel types | Good | Fair | Poor |